Predetermined Overhead Rate Explained: Formula & Guide

This rate is calculated by dividing the estimated manufacturing overhead cost for a period by the estimated total units in the allocation base for that same period. Using a predetermined overhead rate allows companies to apply manufacturing overhead costs to units produced based on an estimated rate, rather than actual overhead costs. This rate is then used throughout the period and adjusted at year-end if necessary based on actual overhead Online Bookkeeping costs incurred. Added to these issues is the nature of establishing an overhead rate, which is often completed months before being applied to specific jobs.

Monitoring relative expenses

- The company has direct labor expenses totaling $5 million for the same period.

- High Challenge Company allocated manufacturing overhead costs to the two products for the month of January.

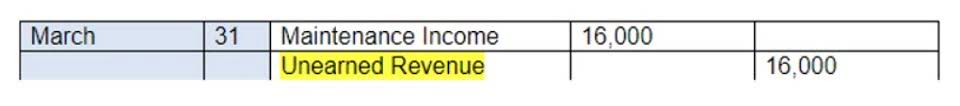

- That amount is added to the cost of the job, and the amount in the manufacturing overhead account is reduced by the same amount.

- Using last year’s overhead rate without considering changes can lead to pricing mistakes.

- It’s because it’s an estimated rate and can be predicted at the start of the project.

- This rate is calculated by dividing the total estimated overhead costs for the period by the total estimated activity base for all production departments combined.

- As with the traditional overhead allocation method, the actual overhead costs are accumulated in an account called manufacturing overhead and then applied to each of the products in this step.

One of the advantages of predetermined overhead rate is that businesses can use it to help with closing their books more quickly. This is because using this rate allows them to avoid compiling actual overhead costs as part of their closing process. Nonetheless, it is still essential for businesses to reconcile the difference between the actual overhead and the estimated overhead at the end of their fiscal online bookkeeping year.

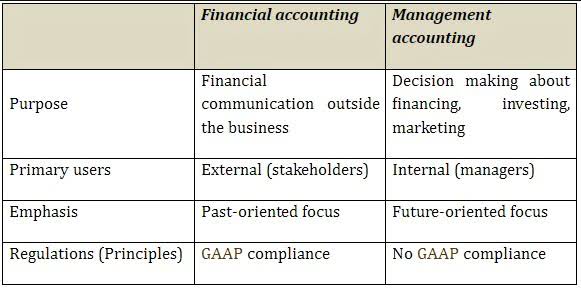

Direct Costs Versus Indirect Costs

- Job costing is commonly used by construction companies, where costs vary widely from job to job.

- Distribute overhead costs to different cost centers or activities based on appropriate allocation methods, such as direct labor hours or machine hours.

- To calculate a predetermined overhead rate for mixed costs, the fixed and variable portions must be separated.

- Analysis More overhead is allocated to the lower volume mountain bicycles using activity-based costing.

Analyzing overhead rates by department in this manner helps identify problem areas and opportunities to improve profitability. And then, allocate those expenses to the expected total number of units of products that the entity expected to produce for the same period. The concept of calculating Predetermined Overhead Rate is using the expected total overhead that is hoping to incur for the whole period. If there are no significant changes, the Predetermined Overhead Rate will be kept for use in the predetermined overhead rate following year. The rate is calculated based on the assumption, and mostly there is small material that we could not avoid.

Hey! Are you looking for a job?

- These rates can be calculated using predetermine overhead formula by using estimated manufacturing overheads and estimated units of production or other valid basis.

- The calculation of the plantwide overhead rate first requires gathering the following information.

- Now management can estimate how much overhead will be required for upcoming work or even competitive bids.

- It’s a good way to close your books quickly, since you don’t have to compile actual manufacturing overhead costs when you get to the end of the period.

- These estimates were made last year and will be used during all of the current year.

- The activity base needs to be a measure which will apply the manufacturing overhead to the products on a fair and impartial basis.

Disadvantages include the extra work and commitment it takes and investment in new technology like payroll processing services and accounting software. (b) Alternatively, we use machine hour rate if in the factory or department of the production is mainly controlled or dictated by machines. These estimates were made last year and will be used during all of the current year. In practice, companies most frequently set rates for the entire year, although some set rates for shorter periods, such as a quarter. The calculation of the plantwide overhead rate first requires gathering the following information. If you’re running several warehouses, calculate separate rates for each location.

By understanding how to calculate this rate, business owners can better control their overhead costs and make more informed pricing decisions. Finally, if the business uses material costs as the activity base and the estimated material costs for the year is 160,000 then the predetermined manufacturing overhead rate is calculated as follows. If a job in work in process has recorded actual labor costs of 6,000 for the accounting period then the predetermined overhead applied to the job is calculated as follows.